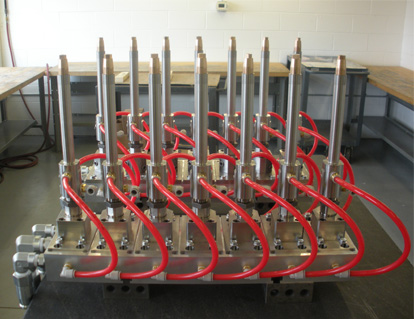

Blow Tooling

Monroe Mold has the expertise to design, build, or repair blow pin and take-out tooling for your blow mold machines. If you have a new mold set, we are able to provide you the new auxiliary tooling to go along with it.

If you have things like deflashing, or facing and reaming that are needed, we have the resources and expert toolmakers who are highly skilled and who can design and build the appropriate blow mold tooling for your existing machine.

Need replacement parts? Look no further than Monroe Mold. We maintain a large inventory of parts and have the experts who can repair or replace damaged parts or tooling for blow molds within a short amount of time.

Extrusion Blow Molding

Extrusion blow molding is one of the simplest types of blow molding where a hollow tube (parison) is formed. To do this, material is forced between a die and mandrel. The parison is then enclosed by two halves of a mold cavity and the bottom is sealed. The neck of the bottle is formed with blow pins that are inserted into the top of the tube. The parison is then expanded with compressed air to force it against the cooled mold cavity walls. Once cooled off, the container is removed from the mold and trimmed of excess plastic or flash. That flash does not go to waste and is reprocessed.

Advantages of Extrusion Blow Molding:

- Mold tooling costs are lower

- Flexibility of tooling and production

- Interchangeable neck and body sections can be accommodated by the molds.

- Adjustable bottle weights.

- Neck inner diameters can be easily controlled to varying requirements.

- Can accommodate large range of container sizes (less than 1 oz. to more than 55 gallons).

- Wide selection of machine sizes.

- Varying sizes of bottles – long and flat or have handles.

Custom Tooling:

Monroe Mold can provide any type of custom tooling to fit your packaging needs. Visit our contact us page for a consultation. We have custom variations to stock bottle tooling including:

- Stock container embossing through the use of a sleeve

- Versatility closure with the use of neck rings, including specialty closures

- Customized capacity or height with the use of inserts